9 Pennsylvania Ave, Corry, PA 16407

814.664.9069

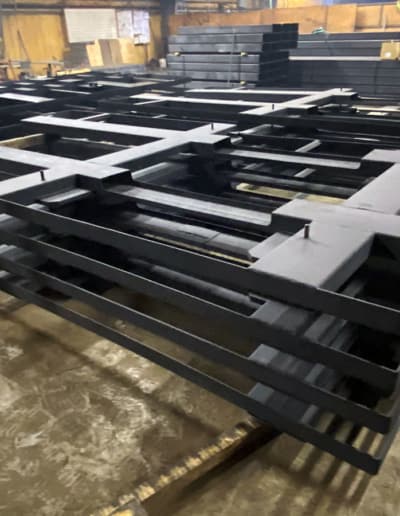

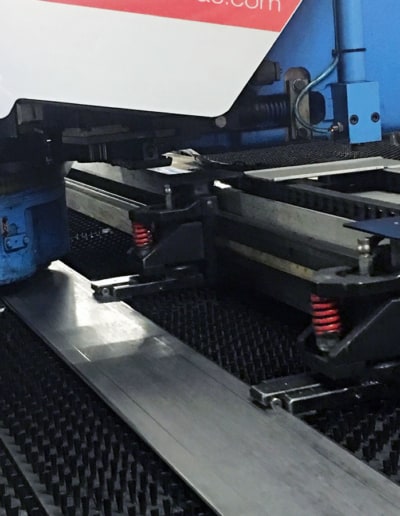

Hensa STMP is a full-service stamper, fabricator, and finisher of metal products with a 40-year history. We have served customers in the plumbing, medical, furniture, automotive, power generation, and shipping industries, among others. Our delivery capabilities range from specialty applications and product development to high volume recurring products with ongoing kitting and distribution.